Most Innovative End-to-End Steel Frame Building System

Pinnacle System: Seamless Integration of Design and Precision Production

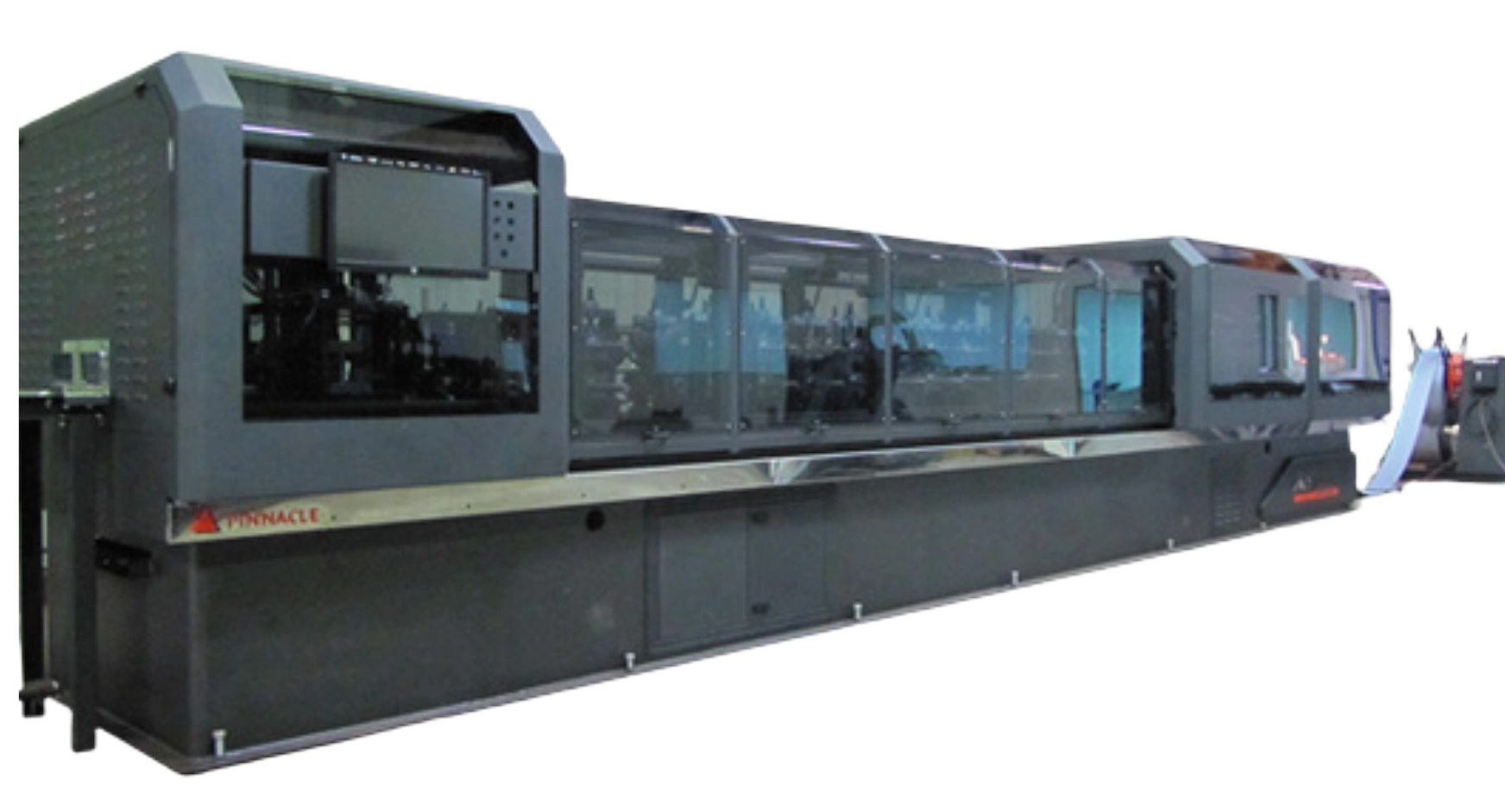

The Pinnacle System is a fully integrated cold formed steel / light gauge steel construction solution that combines advanced design-engineering software with cutting-edge steel framing machines, creating a streamlined and efficient workflow from concept to construction. This seamless connection between digital design and physical production ensures flexible design capabilities, precise execution, and optimized project timelines.

At the core of the Pinnacle System is our powerful design software – PinnacleCAD. This intelligent platform enables architects, engineers, and builders to create highly detailed, customizable designs for any project. Whether working on residential homes & mid-rise buildings, commercial buildings, or industrial structures, the software allows for complete flexibility in terms of layout, dimensions, and specifications, adapting to unique project requirements. It also ensures that every detail, from wall placements to structural components, is accounted for with pinpoint accuracy.

Once the design is finalized, the software directly communicates with our steel framing machines to initiate production. This seamless link eliminates the need for manual data entry or adjustments, reducing the potential for human error and ensuring that the design is translated into perfectly formed steel components. The machines, powered by state-of-the-art cold roll-forming technology, produce each steel element with high precision, ensuring that every piece is cut, shaped, and assembled according to the exact specifications of the digital blueprint.By connecting design and production in one cohesive system, the Pinnacle System offers a smarter, more efficient approach to construction. It reduces lead times, enhances project accuracy, and allows builders to deliver high-quality structures with unmatched precision and consistency, meeting the evolving demands of the construction industry.

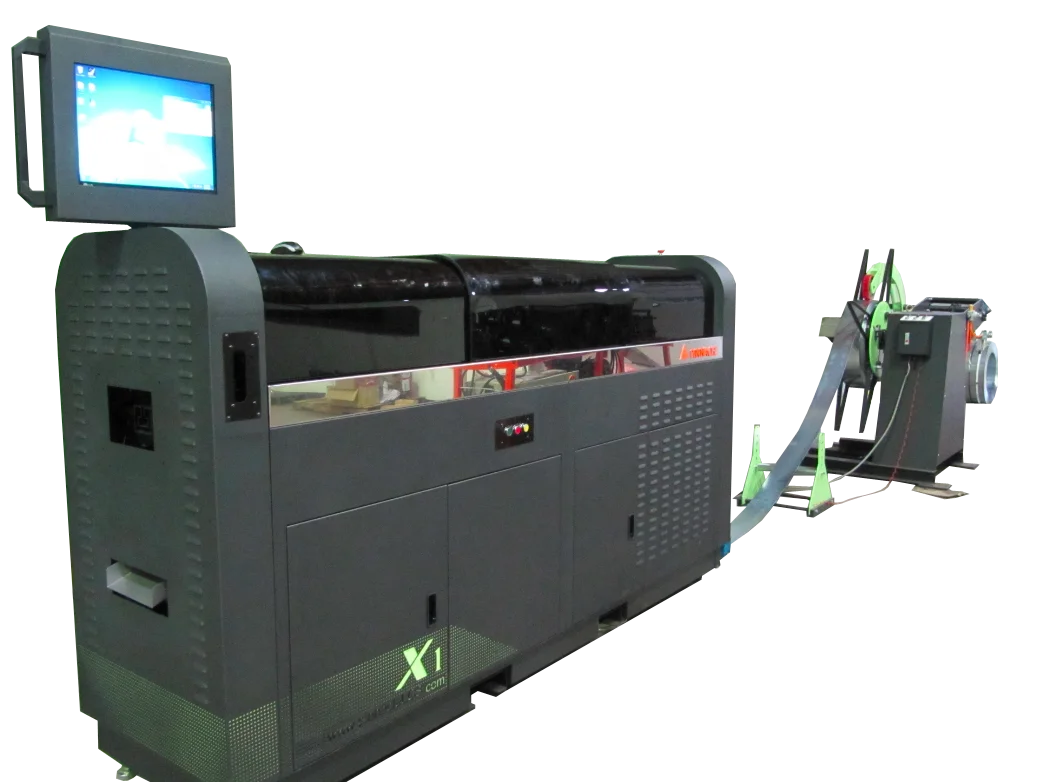

Light Gauge Steel Framing Machines