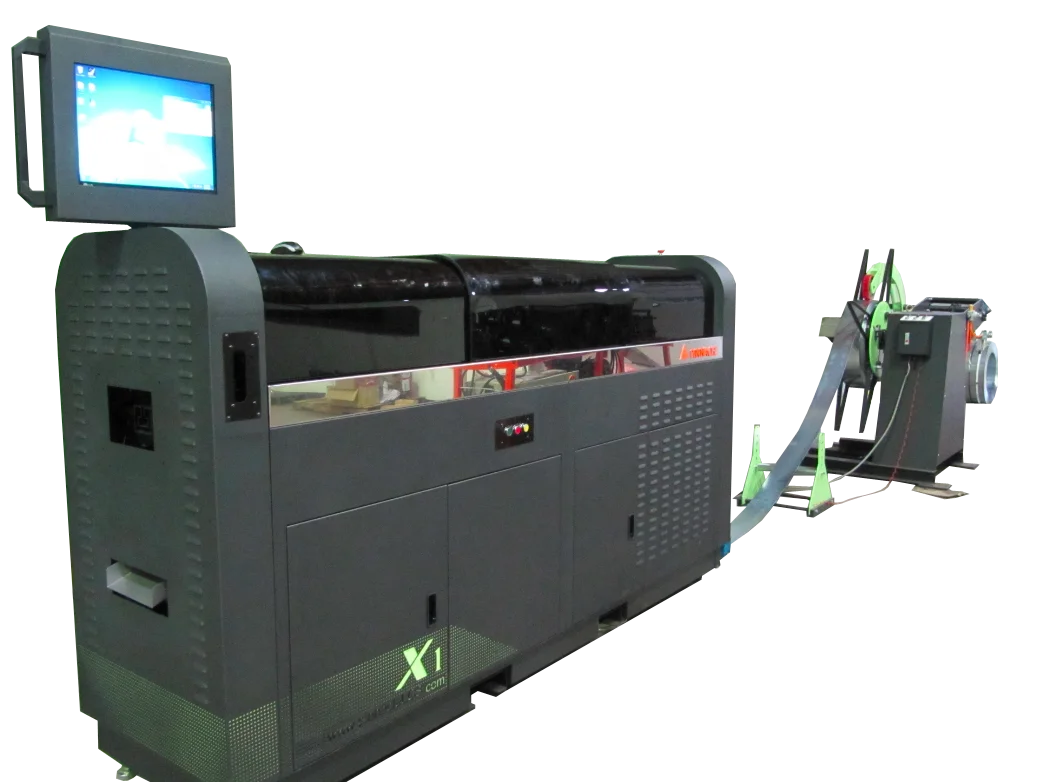

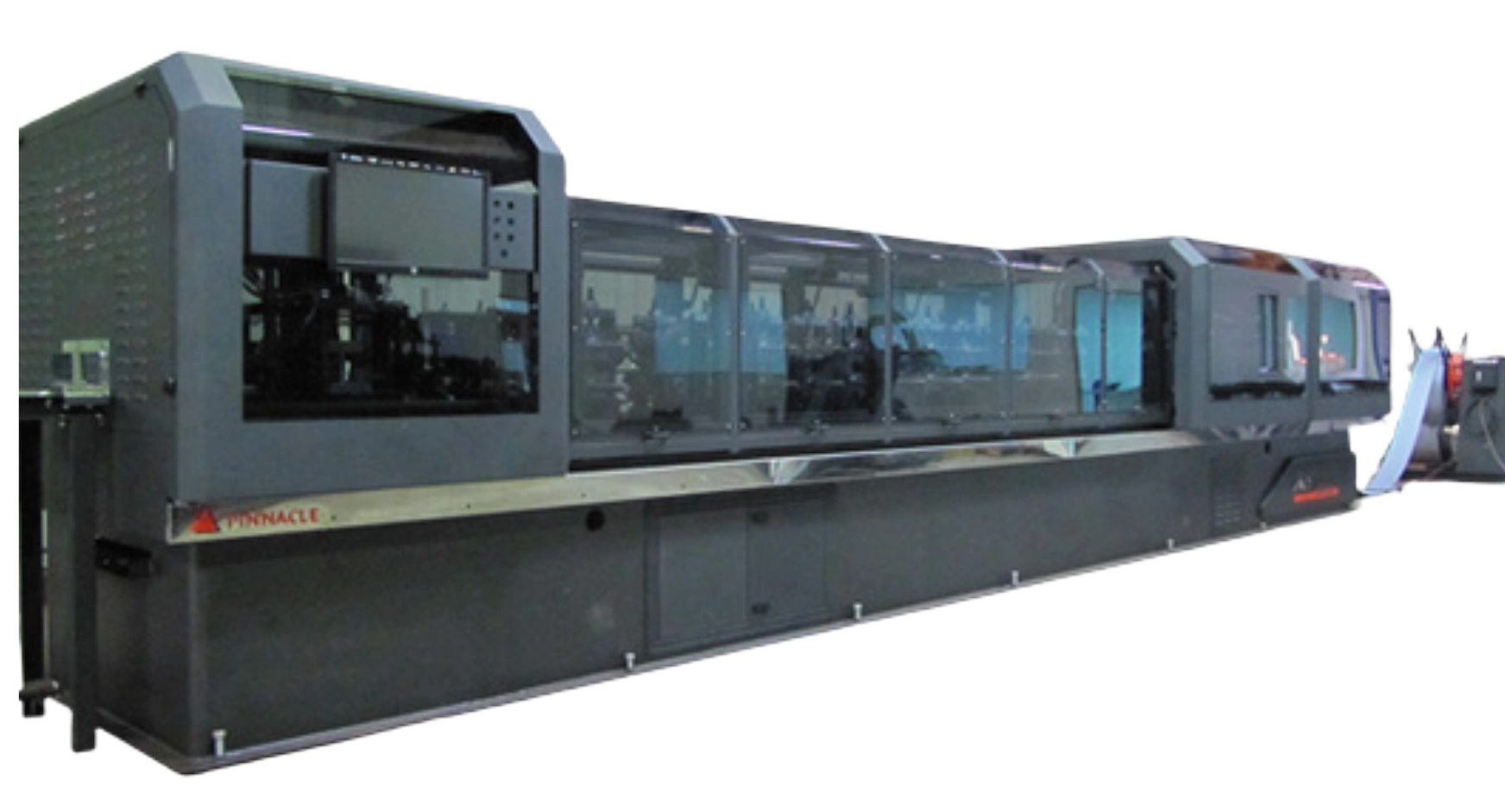

X1 System

(18 Gauge, 1.2 mm Steel Thickness)

(16 Gauge, 1.6 mm Steel Thickness)

(14 Gauge, 2.0 mm Steel Thickness)

Single-profile machine

- 1 Profile size

- Automatic Tooling changeover

- Fully computerized wall, floor and roof truss frame manufacturing system

- Suitable for up to 3-story buildings

- Specifications

- Applications

X1- 18ga – System Specifications

| Model: | PinnacleFRAMER X1-18ga Structural Frame & Truss Design Production System World’s First & Only, Globally Patented | |

| Integrated Software: | PinnacleCAD Engineering Calculation PinnacleCAD 3D Modeling Detailing PInnacleCAD Machine Control Factory | |

| Stud Track Framing: Truss Framing: | C+C or C+U C+C In-Line | |

| Number of Profile: | 1 Dedicated Profile Size between 50mm (2.5”) to 150mm (6”) | |

| Standard Profile Sizes: | Metric Measurement: 50mm x 41mm x 6mm 60mm x 41mm x 10mm 75mm x 41mm x 13mm 90mm x 41mm x 13mm 100mm x 41mm x 13mm 140mm x 41mm x 13mm 150mm x 41mm x 13mm | Imperial Measurements: 2” x 1.625” (200S162) 2.5” x 1.625” (250S162) 3”x 1.625” (300S162) 3.5”x 1.625” (350S162) 3.625”x 1.625” (362S162) 4”x 1. 625” (400S162) 5.5”x 1. 625” (550S162) 6”x 1. 625” (600S162) |

| Material Thickness: | 25 gauge to 18 gauge (0.6mm to 1.2mm) | |

| Roll Forming: | 9 Stations, Auto-Gauging | |

| Frame / Truss Punch Tools: | Service hole punch Left / right lip notch punch Web notch punch Truss end cut punch Flange dimple connection hole punch Shear cut End crimp punch Auto swage | |

| ID Printing System: | Inkjet Printer Fully Integrated for Profile Individual ID Marking | |

| Standard Production Speed (Output): | Walls Frames: 500m/h to 900m/h ( 1,640 to 2,952 LF/hr ) Roof Truss: 300m/h to 500m/h ( 984 to 1,640 LF/hr ) Floor Truss: 200m/h to 300m/h ( 640 to 960 LF/hr ) | |

| Machine Maximum Line Speed: | Up to 2100m/h ( 6,890 LF/hr ) | |

| Main Drive System: | SERVO Driven High Speed System | |

| Main Hydraulic System: | All Temperature Environment, High Power, High Speed System | |

| Machine Length/Width/Height: | 4400mm x 850mm x 1500mm (157.5” x 33.5” x 59.1”) | |

| Weight (Approximate): | 3200 kg (7000lb) | |

| Power Consumption / Supply: | 3 Phase 380 VAC 16 KW / 30 KVA (per client request) | |

| Profile Receiving System: | Standard Run-out table | |

| Powered De-Coiler: | 1,500 kg (3,300lb) Powered Variable Speed Coil Feeding System Maximum width: 300mm Maximum inner diameter: Ø450mm-520mm Maximum outer diameter: Ø1500mm | |

X1- 16ga – System Specifications

| Model: | PinnacleFRAMER X1-16ga Structural Frame & Truss Design Production System World’s First & Only, Globally Patented | |

| Video: | https://pinnaclelgs.com/Framing_Machines.aspx?MenuID=1131 | |

| Integrated Software: | PinnacleCAD Engineering Calculation PinnacleCAD 3D Modeling Detailing PInnacleCAD Machine Control Factory | |

| Stud Track Framing: Truss Framing: | C+C or C+U C+C In-Line | |

| Number of Profile: | 1 Dedicated Profile Size between 63mm (2.5”) to 150mm (6”) | |

| Standard Profile Sizes: | Metric Measurement: 63mm x 41mm x 10mm 75mm x 41mm x 13mm 90mm x 41mm x 13mm 100mm x 41mm x 13mm 140mm x 41mm x 13mm 150mm x 41mm x 13mm | Imperial Measurements: 2.5” x 1.625” (250S162) 3”x 1.625” (300S162) 3.5”x 1.625” (350S162) 3.6”x 1.625” (362S162) 4”x 1. 625” (400S162) 5.5”x 1. 625” (550S162) 6”x 1. 625” (600S162) |

| Material Thickness: | 25 gauge to 16 gauge (0.6mm to 1.6mm) | |

| Roll Forming: | 9 Stations, Auto-Gauging | |

| Frame / Truss Punch Tools: | Service hole punch Left / right lip notch punch Web notch punch Truss end cut punch Flange dimple connection hole punch Shear cut End crimp punch Auto swage | |

| ID Printing System: | Inkjet Printer Fully Integrated for Profile Individual ID Marking | |

| Standard Production Speed (Output): | Walls Frames: 500m/h to 900m/h ( 1,640 to 2,952 LF/hr ) Roof Truss: 300m/h to 500m/h ( 984 to 1,640 LF/hr ) Floor Truss: 200m/h to 300m/h ( 640 to 960 LF/hr ) | |

| Machine Maximum Line Speed: | Up to 2100m/h ( 6,890 LF/hr ) | |

| Main Drive System: | SERVO Driven High Speed System | |

| Main Hydraulic System: | All Temperature Environment, High Power, High Speed System | |

| Machine Length/Width/Height: | 4500mm x 850mm x 1500mm ( 177.2” x 33.5” x 59.1” ) | |

| Weight (Approximate): | 3500 kg (7700lb) | |

| Power Consumption / Supply: | 3 Phase 380 VAC 17 KW / 30 KVA (per client request) | |

| Profile Receiving System: | Standard Run-out table | |

| Powered De-Coiler: | 1,500 kg (3,300lb) Powered Variable Speed Coil Feeding System Maximum width: 300mm Maximum inner diameter: Ø450mm-520mm Maximum outer diameter: Ø1500mm | |

X1- 14ga – System Specifications

| Model: | PinnacleFRAMER X1-14ga Structural Frame & Truss Design Production System World’s First & Only, Globally Patented | |

| Integrated Software: | PinnacleCAD Engineering Calculation PinnacleCAD 3D Modeling Detailing PInnacleCAD Machine Control Factory | |

| Stud Track Framing: Truss Framing: | C+C or C+U C+C In-Line | |

| Number of Profile: | 1 Dedicated Profile Size between 100mm (4”) to 250mm (10”) | |

| Standard Profile Sizes: | Metric Measurement: 100mm x 51mm x 16mm 140mm x 51mm x 16mm 150mm x 51mm x 16mm 200mm x 51mm x 16mm 250mm x 51mm x 16mm Floor Joists: 200mm x 51mm x 16mm 250mm x 51mm x 16mm | Imperial Measurements: 4”x 2” (400S200) 5.5”x 2” (550S200) 6”x 2” (600S200) 8”x 2” (800S200) 10”x 2” (1000S200) Floor Joists: 8”x 2” (800S200) 10”x 2” (1000S200) |

| Material Thickness: | 25 gauge to 14 gauge (0.6mm to 2.0mm) | |

| Roll Forming: | 10 Stations, Auto-Gauging | |

| Frame / Truss Punch Tools: | Truss Index hole punch Flange bolt hole punch Small & Large service hole punch (Floor Joists) Left / right lip notch punch Web notch punch Truss end cut punch Flange dimple connection hole punch Shear cut End crimp punch Auto swage | |

| ID Printing System: | Inkjet Printer Fully Integrated for Profile Individual ID Marking | |

| Standard Production Speed (Output): | Walls Frames: 500m/h to 900m/h ( 1,640 to 2,952 LF/hr ) Roof Truss: 300m/h to 500m/h ( 984 to 1,640 LF/hr ) Floor Joist: 700 m/h to 1,700m/h ( 2,240 to 5,440 LF/hr ) | |

| Machine Maximum Line Speed: | Up to 2100m/h ( 6,890 LF/hr ) | |

| Main Drive System: | SERVO Driven High Speed System | |

| Main Hydraulic System: | All Temperature Environment, High Power, High Speed System | |

| Machine Length/Width/Height: | 6100mm x 1300mm x 1700mm (240.2” x 51.2” x 66.9”) | |

| Weight (Approximate): | 3800 kg (8300lb) | |

| Power Consumption / Supply: | 3 Phase 380 VAC 28 KW / 40 KVA (per client request) | |

| Profile Receiving System: | Standard Run-out table or Automatic Receiving Stacking System | |

| Powered De-Coiler:Configure according to section width | 1500/3000 kg (3,300/6,600lb) Powered Variable Speed Coil Feeding System Maximum width: 300mm/400mm Maximum inner diameter: Ø450mm-520mm Maximum outer diameter: Ø1500mm | |

- Low Rise Residential Building Structures

- Mid Rise Residential Building Structures up to 3 Floors

- Student & Staff Accommodation Facilities up to 3 stories

- Floor & Roof Truss production

- Portable Buildings & Cabins

- Light Modular Building Structures

- Light Commercial and Industrial Building Structures